- FMA

- The Fabricator

- FABTECH

- Canadian Metalworking

Business Profile: Sable Metal Fabrication

Adding automation to a 7-axis press brake in a 10-man company, Sable Metal Fabrication in Markham, Ont., changed more than just throughput. It showed the industry the progressive nature of the company. The willingness to invest in new technology attracted jobs for the semiautomatic laser cutting processes as well as the brake and caused a retooling of the company workforce.

- By Sue Roberts

- April 1, 2016

- Article

- Automation and Software

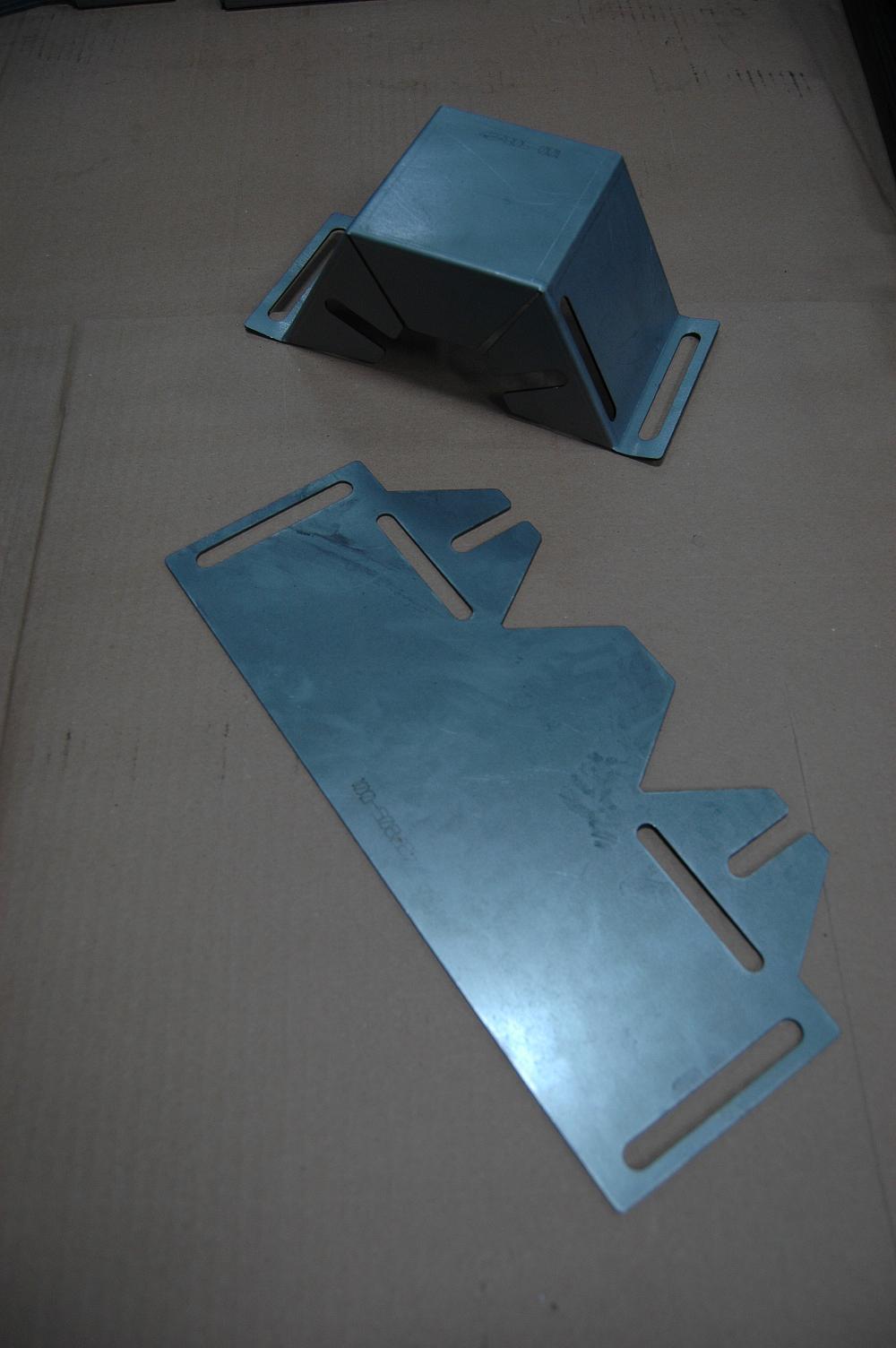

Once flats from the semiautomatic laser cutting tables are positioned, the unmanned press brake cell can complete the bends.

Not many years ago small shops providing customers with part quantities beginning with one weren’t considered ideal robotic environments. Robots were installed at OEMs with dedicated runs or shops that provided thousands of like parts per batch.

But things changed. Continued industry pressure to increase throughput, improve part quality, and reduce labour costs joined with new, easier-to-program, more flexible robotics. Robots then began taking up floor space in job shops where every order can have a different quantity, often low, of parts.

Sable Metal Fabrication in Markham, Ont., is one small shop that differentiated itself by integrating a Motoman HP50 robot with a 10-ft., 7-axis, Aizawa hydraulic press brake nearly eight years ago. Ten employees provide laser cutting and bending services for prototypes, single parts, and runs in the thousands.

Keeping Jobs Here

The addition of the robot helped the brake keep up with bending flats cut on the company’s semiautomatic laser cutting systems … and kept a job from leaving Canada.

“We added the robot to keep one specific job in North America,” said Scott Harnett, president at Sable. “The job, a small part with complex bends, was headed overseas. The robot gave us the capability to keep the project here at a competitive price, and the job justified our investment in the robotics.”

A second regular customer was pulled in based on the reliability of the robotic bending process. “We ran 2,000 to 3,000 pieces at a time, totally unmanned. It was fantastic,” he said. Unfortunately, that job was lost because the U.S. company pulling jobs back across the border.

Harnett said, “That work simply went away. There were no price or production issues. Leading up to 2012 we had amazing, record years, and the robot allowed us to increase our margins on our brake jobs.”

Growing the Company

Losing the job was disappointing, but it didn’t hinder the growth or the direction of the company. Sable moved from its leased, 9,000-sq.-ft.facility into its own building in 2013, where it has the option to double in size. It currently occupies 13,000 sq. ft., a 25 per cent increase in floor space, and leases the remainder of the building.

Equipment includes the 7-axis brake with automation, lights-out laser cutting machines, and complete order tracking software.

Moving wasn’t easy. “We had to reset the robot when we moved and restaff and retool the company,” Harnett said. “Sometimes people are a little resistant to change, like when we added the robotics, and that can bog a company down. When we brought in new people, the learning curve started over again. So, we’re not quite up to utilizing the robot as much as we could yet, but that will happen. The training is coming along and people are getting more confident.

“It’s all about training staff to be competent at the different areas of fabrication that we perform and to change their perspectives on how they see certain jobs. They need to be able to identify the jobs that should be channeled towards the robot.”

Criteria for jobs to add to those already passing through the press brake robotic cell includes tolerance, volume, frequency, and job longevity.

Harnett said, “As training continues we will attack the highest-frequency, longest running parts with the most generous margins first because they will be the easiest.”

Volume and frequency affect the decision because of programming and setup time. “It’s not just that we are doing 2,000 pieces, but are we doing them in batches of 200 a month or in orders of 1,000 every six months?” If a run is expected to end after six months, it will have a lower priority for the robotic cell and most likely head to one of the manual brakes.

Adding the robot to the shop has had the unexpected benefit of bringing in jobs that don’t involve bending.

“We have always been automation-minded,” said Harnett. “Our lasers are semiautomated and the press brake robot was a complement to that. When people see the brake cell on our website, they get the sense of the shop’s progressive mentality. It tells them that if we are willing to invest in the robot, they will benefit from that attitude whether or not their job requires its use. Our willingness to invest in new technology shows that we are always striving to do things better, more efficiently, and that is appreciated in this industry.”

Planning the Next Move

That progressive attitude has Harnett looking ahead to the next addition, partly to support the robot already on the floor. That will be additive manufacturing.

“We are going to use this new technology to build things that will make the robot more productive. It needs a lot of support—fixtures, jigging, support for end-of-arm tools—and we would like to be able to make those components in-house. If we can print them rather than machine them or use CAD to produce them from sheet metal--which has its limitations--it will help us with faster robot changeovers.”

Harnett’s advice to anyone considering entering the world of robotics: “Have the right people from the beginning. You can spend a lot of time hitting your head against the wall if you don’t have the people to program the robot and who understand what jobs are right for it.

“Robots can be a hit or miss. One small shop can add a robot and really excel. The same robot in another shop with the same jobs but different people can fail miserably. The staff around the robot is key.

“We have the staff to help our customers grow and be competitive which, in turn, helps us grow and remain competitive.”

Associate Editor Sue Roberts can be reached at sroberts@canadianfabweld.com.

Sable Metal Fabrication, 905-948-1282, www.sablemetal.com

About the Author

Sue Roberts

2135 Point Blvd

Elgin, IL 60123

815-227-8241

Sue Roberts, associate editor, contributes to both Canadian Metalworking and Canadian Fabricating & Welding. A metalworking industry veteran, she has contributed to marketing communications efforts and written B2B articles for the metal forming and fabricating, agriculture, food, financial, and regional tourism industries.

Roberts is a Northern Illinois University journalism graduate.

subscribe now

Keep up to date with the latest news, events, and technology for all things metal from our pair of monthly magazines written specifically for Canadian manufacturers!

Start Your Free Subscription- Trending Articles

Class is in session for college connections

BlueForge Alliance partners with Nuts, Bolts & Thingamajigs to develop Submarine Manufacturing Camps

Engine-driven welding machines include integrated air compressors

Orbital tube welding webinar to be held April 23

Portable system becomes hot tech in heat treatment

- Industry Events

ZEISS Quality Innovation Days 2024

- April 15 - 19, 2024

Tube 2024

- April 15 - 19, 2024

- Düsseldorf, Germany

CTMA Economic Uncertainty: Helping You Navigate Windsor Seminar

- April 30, 2024

- Windsor, ON Canada

MME Winnipeg

- April 30, 2024

- Winnipeg, ON Canada

CTMA Economic Uncertainty: Helping You Navigate Kitchener Seminar

- May 2, 2024

- Kitchener, ON Canada